Defense & Security

Development of South Korea’s Tanks and the Global Competitiveness of the K2 Black Panther

Image Source : shutterstock

Subscribe to our weekly newsletters for free

If you want to subscribe to World & New World Newsletter, please enter

your e-mail

Defense & Security

Image Source : shutterstock

First Published in: Oct.15,2025

Oct.15, 2025

1. Introduction

Since the Korean War, South Korea had long relied on U.S.-made tanks, but in the 1970s it launched a full-scale domestic tank development program under the principle of self-reliant national defense. As a result, beginning with the K1 tank, the country gradually increased its localization rate, and today it has fielded the highly advanced K2 Black Panther, placing itself among the world’s leading tank powers. However, when compared to major tanks competing in the global defense market, a comprehensive analysis is still required not only in terms of performance, but also in cost-effectiveness and export competitiveness. This study examines the evolution and localization of South Korea’s tanks, and analyzes the performance of the K2 in comparison with other global competitors to highlight its export potential and strategic significance.

2. Early Background: The Korean War – Early 1970s

During the Korean War 1950-1953, North Korean forces launched their invasion spearheaded by the Soviet Union’s best-selling tank, the T-34. In contrast, South Korea did not possess a single tank at the time. The power of the T-34 allowed the North Korean army to advance rapidly in the early stages of the war. However, the arrival of U.S. ground forces changed the situation. The M24 Chaffee light tank was the first to be deployed, followed by the M4 Sherman medium tank, the M26 Pershing heavy/medium tank, and the M46 Patton medium tank, all of which overwhelmed the North Korean forces. Thanks to this reinforcement, the Nakdong River defensive line was held, and the tide of the war shifted in favor of the UN forces. Additionally, by late 1950, the British Army had committed its renowned A41 Centurion tanks to the conflict. After the war, in 1959, South Korea received the M47 Patton tank from the United States as part of its allied support policy and broader equipment modernization program.

After the war, South Korea relied on U.S. assistance until 1970 to accumulate experience in operating and maintaining tanks. In particular, in 1966, when the M48 Patton tanks were provided by the United States, South Korea also received a Technical Data Package (TDP), which included key technology transfers alongside major upgrades. Through this, South Korea acquired comprehensive expertise in armor casting and welding, production processes, precision manufacturing and assembly, as well as quality inspection and testing. This foundation became a crucial stepping stone for the subsequent development of the Korean tank industry.

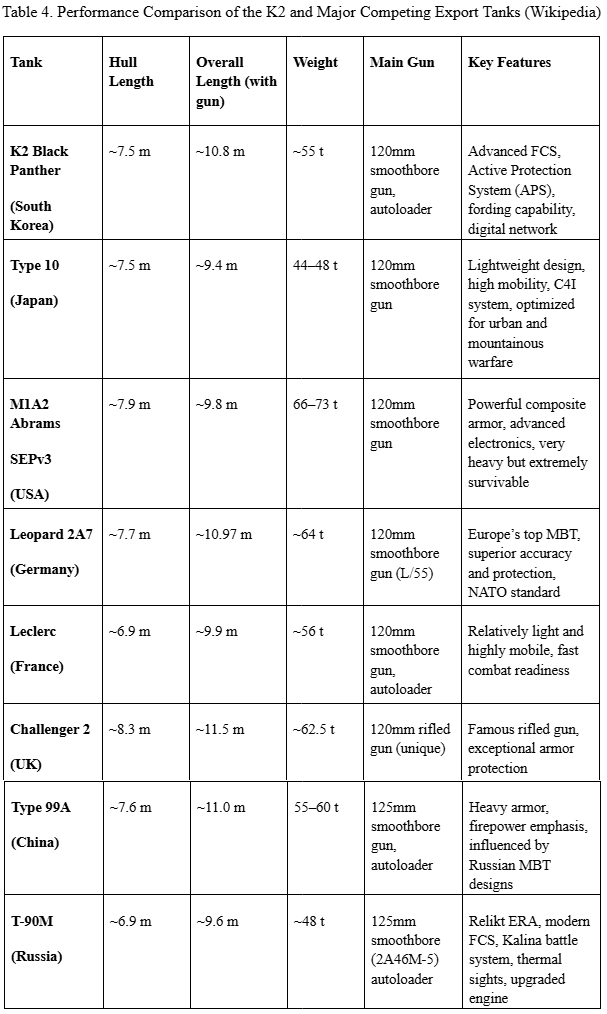

3. Development of the K1 Indigenous Tank: 1970s–1980s

Under President Park Chung-hee’s policy of self-reliant national defense, South Korea launched the Republic of Korea Indigenous Tank (ROKIT) program in 1975 in cooperation with the United States. Following the signing of a memorandum of understanding in 1978, full-scale development began. The design direction was set to base the new tank on the form and performance of the U.S. Army’s latest third-generation tank at the time, the M1 Abrams. Chrysler Defense (now GDLS), the manufacturer of the M1, participated in the project, while South Korea’s Agency for Defense Development and Hyundai Precision (now Hyundai Rotem) worked together to create a smaller, terrain-optimized “Little Abrams” for the Korean Peninsula. In April 1984, two prototypes were produced, and after passing a series of tests, mass production began in 1985.

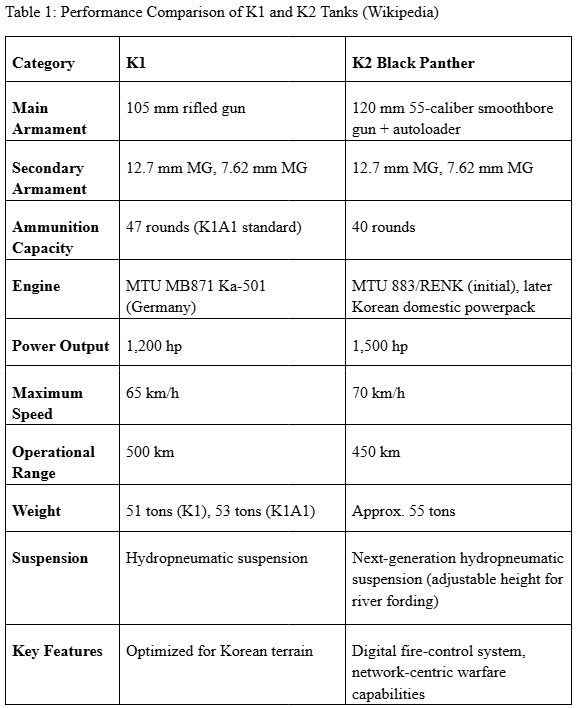

The production K1 tank was armed with a 105 mm rifled gun and equipped with a 1,200 horsepower German MTU-series diesel engine, built with General Dynamics technology. A key feature was the adoption of a hydropneumatic suspension system, allowing adjustable ground clearance suited for Korea’s mountainous terrain. The tank weighed 51.5 tons, carried a crew of four, and a total of 1,026 units were produced between 1985 and 1997.

During its service, the upgraded K1A1 variant was developed, featuring a 120 mm smoothbore gun, improved fire-control systems, and enhanced armor protection. A total of 484 K1A1s were produced between 1996 and 2008. Subsequent modernized versions, the K1E1 and K1E2, have ensured that the K1 series continues to serve as a core component of the South Korean Army’s armored forces.

4. The K2 Black Panther: 2000s – Present

Beginning in 1996, the Republic of Korea Armed Forces acquired 68 T-80U tanks from Russia as repayment for an economic cooperation loan. At the time, the T-80U was Russia’s latest main battle tank, and for South Korean engineers, who had previously only worked with U.S.-made tanks, it provided a valuable opportunity to gain direct experience with a new model. The lessons learned from operating the T-80U contributed significantly to the later development of the K2 tank.

After the Ministry of National Defense announced its next-generation tank program in 1992, a system concept study was carried out in 1995, followed by exploratory development in 1998. In 2003, full-scale system development began. By 2007, three prototypes were unveiled for operational testing and evaluation, and mass production was initially scheduled to begin in 2012. However, issues arose during the development of the domestic powerpack (engine and transmission). These included an engine protection temperature setting error, which failed to safeguard the engine from overheating, and insufficient cooling fan speed in the transmission at maximum output, which led to inadequate cooling.

Despite multiple redesigns, persistent problems in performance and reliability testing delayed deployment. As a result, the first production batch of 100 K2 tanks was equipped with Germany’s MTU engines and RENK transmissions instead of the domestic powerpack. These vehicles began delivery to the ROK Army in April 2014. By September 2014, the domestic engine had passed the Defense Acquisition Program Administration’s evaluation, and the second batch of 106 tanks and the third batch of 54 tanks were produced with a “hybrid powerpack”—a Korean-made engine combined with a German transmission. Starting with the fourth production batch, SNT Dynamics’ domestic transmission was successfully integrated, completing full localization of the K2 powerpack.

Unlike its predecessor, the K1, which had been developed under the leadership of General Dynamics and relied heavily on U.S. components, the K2 Black Panther is a fully indigenous South Korean tank. With domestically developed engines and transmissions, it achieved a high localization rate, giving South Korea independence from U.S. and German export restrictions and allowing greater freedom in operating and exporting its tanks.

As South Korea’s most advanced tank, the K2 incorporates cutting-edge technologies that set it apart from its predecessors. These include a 120 mm smoothbore gun, an active protection system (APS), an autoloader, and stealth features, delivering superior mobility, protection, and firepower. Today, it stands as a core asset of the South Korean Army.

Specifications (K2 Black Panther):

Crew: 3

Weight: 55 tons

Engine: Doosan Infracore DV-27K diesel engine

Transmission: SNT Dynamics EST15K automatic transmission

Main Gun: Hyundai WIA 120 mm smoothbore CN08

Fire Control System: South Korean domestic technology

Armor: Korean-developed composite armor

5. Timeline of South Korea’s Tank Development: From U.S. Aid to the K2

The introduction and development of tanks in the ROK Army have been organized in a chronological timeline with images. This timeline is designed to provide a clear overview of the entire progression — from U.S. aid tanks, to tanks acquired from Russia, and finally to the development of indigenous Korean tanks.

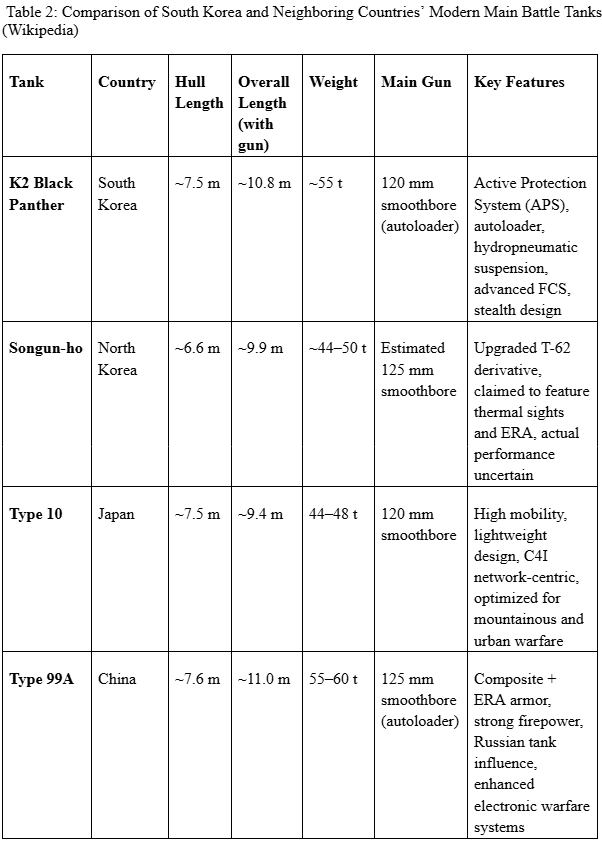

6. K2 vs. Regional Main Battle Tanks — Performance Comparison

Tank performance can be compared across four key categories: Mobility, Firepower, Protection, and Sensors & C4I.

Mobility

Components: engine & transmission (powerpack), suspension, roadwheels, sprockets, tracks, and fuel systems.

Role: determines speed, acceleration, cross-country mobility, and operational range. Maintainability (ease of maintenance and access) is also included here.

Firepower

Components: main armament (gun) — barrel and mantlet, stabilization system, autoloading/manual loading systems, coaxial and anti-aircraft machine guns, ammunition stowage.

Role: defines ability to defeat enemy armor and other targets, hit probability (integrated with the fire-control system), and ammunition variety (e.g., APFSDS, HE).

Protection

Components: baseline composite/steel armor, explosive reactive armor (ERA), active protection systems (APS), smoke generation, fire suppression and NBC protection, and crew survivability compartments.

Role: protects crew and systems from penetration, fragmentation, anti-tank weapons, and environmental threats.

Sensors & C4I (Command, Control, Communications, Computers, and Intelligence)

Components: fire-control system (FCS), thermal and night sights, laser rangefinder, communications suites, electronic warfare and laser warning receivers, and power-management systems.

Role: responsible for target acquisition, firing accuracy, and networked combat — i.e., information sharing with friendly forces.

Below is a comparison of the K2 and the region’s current main battle tanks.

The K2 Black Panther is regarded as a world-class main battle tank, demonstrating well-balanced excellence in mobility, firepower, protection, and electronic systems compared to neighboring countries’ tanks.

7. South Korea’s Tank Export Outlook and Key Cases

While exports of the K1 tank were restricted due to U.S. technology regulations, the K2 tank—developed with fully indigenous Korean technology—became eligible for overseas sales. In 2022, South Korea successfully signed a contract with Poland, and negotiations are currently underway with countries in Europe, the Middle East, and Africa, signaling the expansion of Korean tanks into the global defense market.

7.1. Turkish Joint Development of the Altay Tank Based on the K2 (USD 540 million)

In 2007, South Korea signed a design support and technology transfer contract with Turkey for the development of the Altay main battle tank. Under this agreement, South Korea transferred several core technologies derived from the K2 tank, including:

- 120 mm CN08 smoothbore gun technology (Korean-produced main gun)

Advanced armor and composite equipment design consultation and production support

- Powerpack (engine + transmission) technology transfer and testing: the Altay successfully completed durability trials with the HD Hyundai Infracore engine and SNT Dynamics transmission

The Altay is scheduled to enter full-scale mass production in 2025, with an initial production run of 250 units and a long-term goal of building up to 1,000 tanks.

7.2. K2 Export to Poland: First Batch of 180 Units (USD 3.4 billion), Second Batch of 180 Units (USD 6.5 billion)

In 2022, the K2 tank was selected by Poland over strong competitors such as Germany’s Leopard 2A7 and the U.S. M1A2 Abrams. The key factors behind this successful export were as follows:

- Rapid delivery and phased supply: South Korea demonstrated its ability to deliver tanks within a very short timeframe. Following the 2022 contract, the first batch of 10 units was delivered within the same year. By contrast, competitors faced production line bottlenecks, raising concerns over delivery delays.

- Modern design with European upgrade potential: The K2 features a 120 mm 55-caliber smoothbore gun, an autoloader, an active protection system (APS), and hydropneumatic suspension—technologies equal to or in some cases more advanced than those found in Europe’s latest MBTs. Moreover, South Korea promised to develop a localized version, the K2PL, through joint development with Poland, tailored to Polish requirements.

- Local production and technology transfer: South Korea offered local production of the K2PL, guaranteeing the participation of Polish defense industries, along with technology transfer, industrial cooperation, and the prospect of using Poland as a base for future exports.

- Cost competitiveness: Despite being a state-of-the-art tank, the K2 is relatively more affordable than the M1A2 or Leopard 2A7. Maintenance and sustainment costs are also projected to be lower than those of European tanks, giving the K2 a strong reputation as a “cost-effective MBT” with excellent value for performance.

- Tactical versatility and advanced systems: Equipped with an autoloader, hydropneumatic suspension, and advanced smart fire-control systems, the K2 offers outstanding adaptability across diverse operational environments, including mountainous terrain, urban warfare, and extreme cold.

Through this deal, South Korea and Poland established a relationship that goes beyond a simple arms sale, building long-term defense industry partnership and mutual trust.

Potential export destinations for the K2 include the Czech Republic, Slovakia, Romania, Saudi Arabia, Oman, Egypt, Morocco, and India.

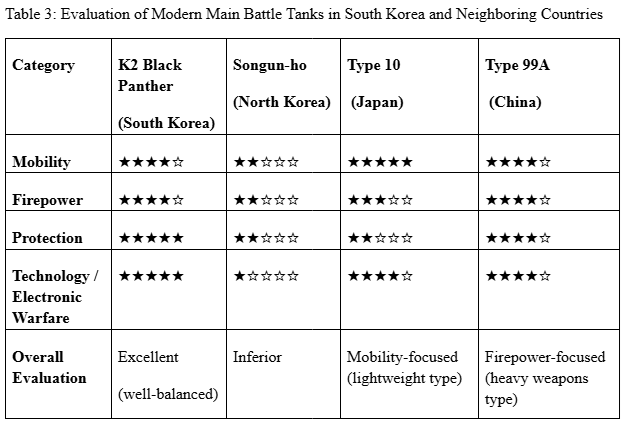

8. Comparison of Tanks from Export Competitor Nations

South Korea’s K2 tank has attracted global attention for its outstanding performance, but the international tank market is already dominated by several major players.

This chapter analyzes and compares the leading tanks that compete with the K2, while also examining each country’s export competitiveness.

The K2 Black Panther, while incorporating cutting-edge technologies, is lighter than many Western main battle tanks, resulting in relatively lower sustainment costs. It is therefore widely regarded as a cost-effective, well-balanced tank.

The cost of a tank varies greatly depending on its design and configuration, but if we break down the production cost (manufacturing, components, and assembly) into four categories, the estimated shares are as follows:

- Protection: 30–40%

- Firepower: 20–30%

- Mobility: 15–25%

- Electronics & C4I: 15–25%

The actual share, however, depends on specific factors. For example, the use of advanced armor materials (composite/uranium) or the inclusion of an Active Protection System (APS) significantly increases protection costs. Similarly, specialized gun and ammunition systems (such as a 120mm smoothbore, autoloader, or advanced munitions) raise firepower costs. Integration, testing, and safety features greatly affect electronics costs, while options like autoloaders, high-performance thermal sights, and networked systems can heavily influence the final balance.

Other important factor is Lifecycle Perspective (Unit Cost vs. Total Life-Cycle Cost), which can be defined as below.

- Procurement: About 20–30% of total life-cycle cost (highly variable)

- Operations & Support (O&S): 60–70% — dominated by fuel, maintenance, spare parts, and maintenance personnel costs

- Upgrades & Depreciation: 10–20%

In other words, the long-term operation and maintenance costs take up a much larger share than the initial procurement cost of a tank.

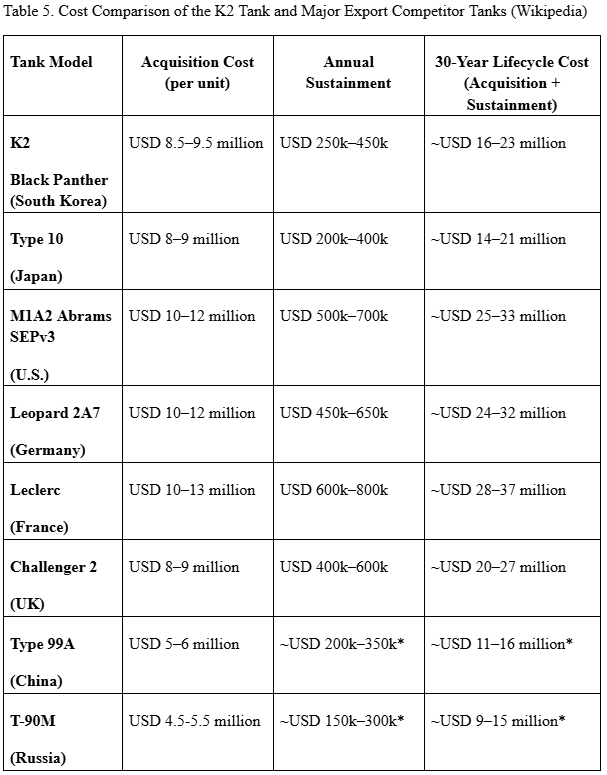

Below is a comparison table of modern main battle tank costs: unit acquisition cost, annual sustainment cost, and 30-year life-cycle cost (procurement + sustainment).

*The sustainment cost for China’s Type 99A and Russia’s T-90M is an estimate.

9. Conclusion

This study has systematically examined the evolution and localization of South Korea’s tanks, and verified the level of their advancement through performance comparisons with leading global competitors. In particular, the K2 has demonstrated balanced capabilities in mobility, firepower, protection, and electronic command-and-control, supported by advanced technologies and a high degree of localization.

At the same time, it offers superior cost-efficiency in sustainment and operational expenses compared to heavier Western MBTs. This makes the K2 not only a key asset for strengthening domestic defense, but also a competitive and cost-effective platform in the global arms market.

Taken together, these findings suggest that South Korea’s tanks have progressed beyond being a mere symbol of self-reliant defense, and are now positioned to expand exports and build long-term strategic partnerships worldwide.

Unlock articles by signing up or logging in.

Become a member for unrestricted reading!